Lithium Ion Cylindrical Cells Vs. Prismatic Cells

Cylindrical and Prismatic Cells are the most common options on the market for building Lithium Batteries. Before you purchase a battery for your application consider the following advantages and drawbacks of each type of cell.

Cylindrical Cells

Cylindrical cells are the most common cell type in use today. This design allows for better automation processes and techniques that increase consistency and lower cost.

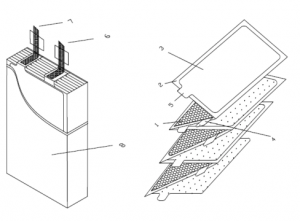

Prismatic Cells

Prismatic cells have gained popularity because their large capacity and prismatic shape that make it easy to connect 4 cells together and create a 12V battery pack.

Compared to prismatic cells, cylindrical cells can be produced much faster so more KWh per cell can be produced every day equaling lower $ per KWh. The electrodes in a cylindrical cell are wound tightly and encased in a metal casing. This minimizes electrode material from breaking up from the mechanical vibrations, thermal cycling from charging and discharging, and mechanical expansion of the current conductors inside from thermal cycling. Many cells are combined in series and in parallel to increase voltage and capacity of the battery pack. If one cell goes bad, the impact on the entire pack is low. CHARGEX® cells bolt through lengthway circuit boards that will prevent a bad cell from shorting out the rest of the pack, allowing it to continue functioning with slightly reduced capacity. With prismatic cells if one cell goes bad it can compromise the whole battery pack. Cylindrical cells will also radiate heat and control temperature better than prismatic cells.

Compared to prismatic cells, cylindrical cells can be produced much faster so more KWh per cell can be produced every day equaling lower $ per KWh. The electrodes in a cylindrical cell are wound tightly and encased in a metal casing, This minimizes electrode material from breaking up from the mechanical vibrations, thermal cycling from charging and discharging and mechanical expansion of the current conductors inside from thermal cycling. Many cells are combined in series and in parallel to increase voltage and capacity of the battery pack, if one cell goes bad, the impact on the entire pack is low. CHARGEX® cells bolt through lengthway circuit boards that will prevent a bad cell from shorting out the rest of the pack, allowing it to continue functioning with slightly reduced capacity. With prismatic cells if one cell goes bad it can compromise the whole battery pack. Cylindrical cells will also radiate heat and control temperature better than prismatic cells. Prismatic cells are made up of many positive and negative electrodes sandwiched together leaving more possibility for short circuit and inconsistency. The higher capacity makes it difficult for the BMS to protect each cell from over charging and dissipating heat. The larger cell size minimizes the possibility for automation leading to a lower degree of consistency. The internal electrodes can easily expand and contract causing deformation which can lead to a internal short circuit and are more prone to swelling similar to lead batteries.

Comments or Questions? let us know how we can help.