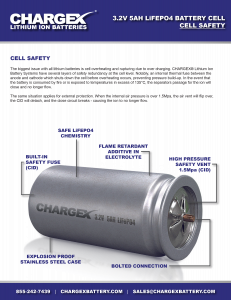

THERMAL FUSE

Internal Cell Safety Fuse

Our cells have a built-in thermal safety fuse between the anode and cathode that will break in the unlikely event the cell overheats.

SAFETY VENT

High Pressure Safety Vent

A high pressure safety vent will flip open to release energy and prevent explosion if exposed to extreme heat.

ELECTROLYTE

Flame Retardant Electrolyte

Our cells are manufactured with a flame retardant additive in the electrolyte making them safe.

EXPLOSION PROOF

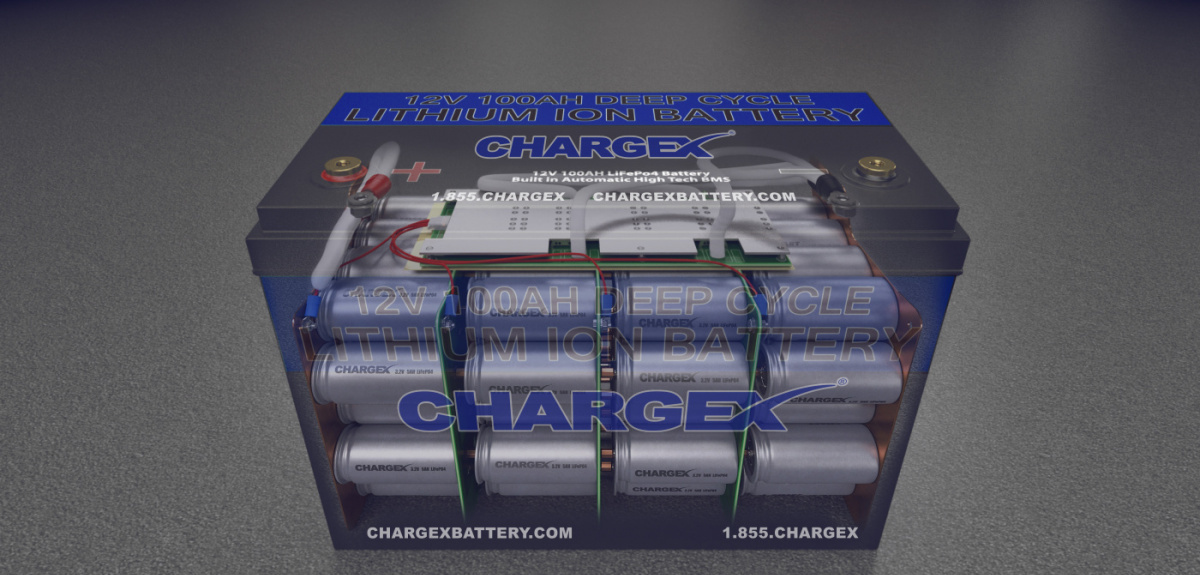

Explosion Proof Stainless Steel

Every Lithium Battery cell is manufactured in an explosion proof stainless steel cylindrical case.